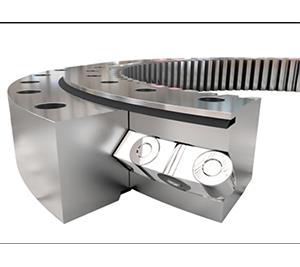

Toothless slewing ring

Home>Product Center > 11 series single row cross roller type

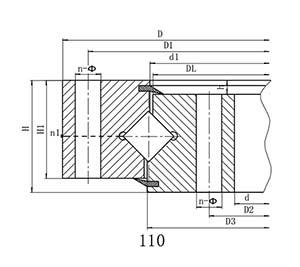

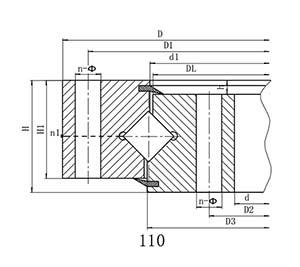

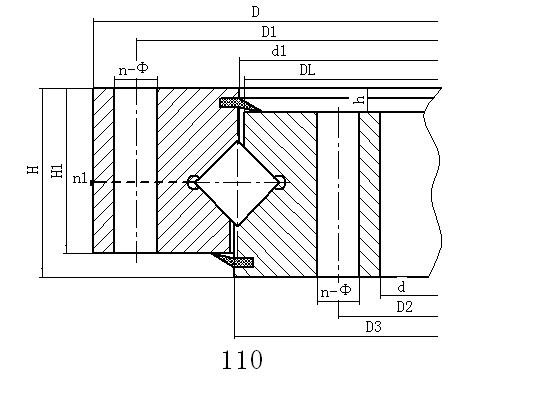

Single-row interspersed roller slewing ring (11 series)-gearless structural features, functions, and scope of application The single-row interspersed roller slewing ring consists of two seat rings, with compact structure, light weight and high manufacturing accuracy. The device has a small gap and high requirements for device accuracy. The rollers are arranged in a 1:1 interleaved arrangement, which can bear axial force, tilting moment and large radial force at the same time, and is widely used in lifting, transportation, construction machinery and military industry. Product. If the rolling surface of the slewing ring is cracked, indented or corroded, periodic vibration and noise like riveting rivets will occur. The period may be fixed, but most of them are related to the speed....

Single row interspersed roller slewing ring (11 series)-gearless

Structural features, functions, scope of application

Single-row interspersed roller slewing ring, composed of two seat rings, compact structure, light weight, high production accuracy, small device clearance, high requirements for device accuracy, rollers are arranged in a 1:1 interspersed arrangement, which can bear the axial direction at the same time Force, tipping moment and large radial force are widely used in lifting and transportation, construction machinery and military products. If the rolling surface of the slewing ring is cracked, indented or corroded, periodic vibration and noise like riveting rivets will occur. The period may be fixed, but most of them have a certain corresponding relationship with the speed. The scars will be continuous on the channel. Occurs, the scars appear and disappear on the steel ball from time to time, and this noise varies with the device and smooth conditions. Control methods for this type of noise: do not knock the bearing during installation, avoid bearing skew when assembling the bearing and the shaft and then install it in the bearing housing; avoid bearing corrosion during inventory and avoid shock and vibration during transportation; use high-viscosity grease .