Light series slewing ring (flange type)-external gear slewing ring (slewing table bearing) has unique load-bearing characteristics, and is usually used on hoisting machinery, excavators, slewing tables, wind turbines, telescopes, tank turrets and other devices . Through the improvement of processing methods and the updating of planning concepts, today's slewing bearings can be used in smaller, more complex and more precise occasions. In the machine tool industry, the slewing bearing of the standard structure adopts a high-precision grade and simultaneously applies a preload to eliminate gaps and reduce vibration. The radial runout and diameter tolerance of the slewing ring are between one thousandth and one ten thousandth of an inch...

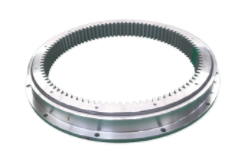

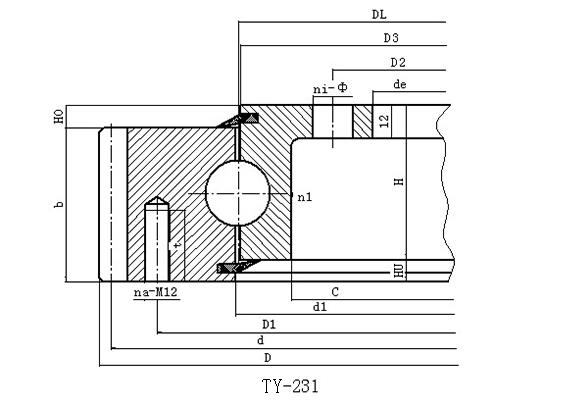

Light series slewing ring (flange type)-external gear type

Slewing bearings (turntable bearings) have unique load-bearing characteristics and are usually used in hoisting machinery, excavators, turrets, wind generators, telescopes, and tank turrets. Through the improvement of processing methods and the updating of planning concepts, today's slewing bearings can be used in smaller, more complex and more precise occasions.

In the machine tool industry, the slewing bearing of the standard structure adopts a high-precision grade and simultaneously applies a preload to eliminate gaps and reduce vibration. The radial runout and diameter tolerances of the slewing bearing range from one thousandth to one ten thousandth of an inch (2.54 tan). The structure is compact, the section size is small, and the diameter can be as small as 50 mm (the steel ball of this type of slewing bearing The size is smaller than the steel ball size of the traditional heavy series slewing bearing). This prompted planners to begin to reconsider traditional slewing bearing equipment.

The correct choice of slewing bearing depends on the requirements of load, stiffness, speed, size and rotational flexibility. The user and the slewing ring manufacturer jointly discuss the planning goals and the applicability of the slewing ring, which helps to achieve better system performance under the premise of minimum cost and guaranteed trouble-free operation.