Three-row roller type external tooth slewing ring

Home>Product Center > 13 series three-row roller slewing ring

Three-row roller slewing bearing (13 series)-external gear structure features, functions, and scope of application The three-row roller slewing bearing has three races, and the upper and lower and radial raceways are separated to make each row of rollers The load can be determined appropriately. It can bear various loads at the same time. It is one of the four products with the largest bearing capacity. The shaft and radial dimensions are large, and the structure is strong. It is especially suitable for heavy machinery requiring larger diameters, such as bucket wheel excavators and wheels. Cranes, marine cranes, port cranes, molten steel running platforms and large-tonnage car cranes. The rationality of each processing technology,...

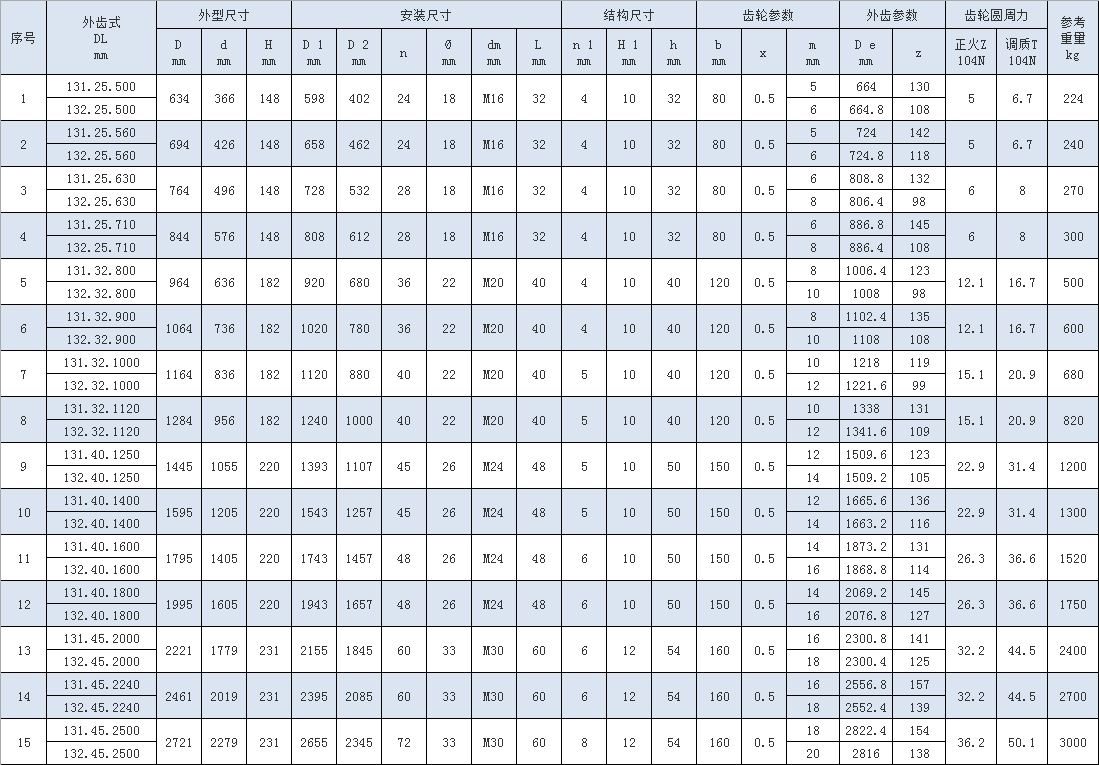

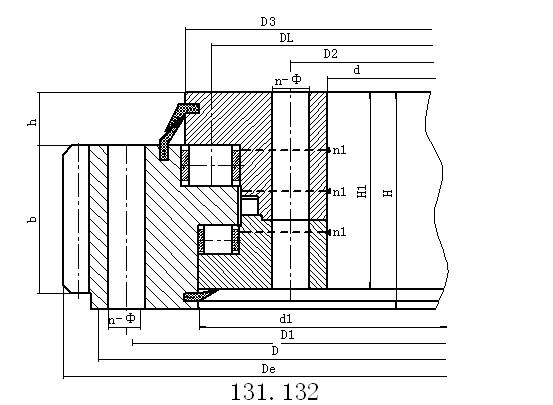

Three-row roller slewing ring (13 series)-external gear

Structural features, functions, scope of application

The three-row roller slewing ring has three races, and the upper, lower and radial raceways are separated, so that the load of each row of rollers can be determined appropriately. It can bear various loads at the same time. It is one of the four products with the largest bearing capacity. The shaft and radial dimensions are large, and the structure is strong. It is especially suitable for heavy machinery requiring larger diameters, such as bucket wheel excavators and wheels. Cranes, marine cranes, port cranes, molten steel running platforms and large-tonnage car cranes.

The rationality, advancement and stability of each processing technology will also affect the life of the slewing ring. In the meantime, the heat treatment and grinding processes that affect the quality of the product slewing ring are often more directly related to the loss of the slewing ring. In recent years, slewing bearing manufacturers' research on the surface degeneration layer of the slewing ring shows that the grinding process is closely related to the surface quality of the slewing ring. The fine grinding treatment of the slewing bearing is related to the later application function, that is, if you do not operate and adjust the equipment according to the operation instruction during the grinding, various defects will appear on the surface of the slewing bearing, which will affect the overall quality of the slewing bearing. It is an important part of industrial parts, but the biggest problem facing the industry now is that there is no improvement. As long as continuous research and development and improvement of product design and structure can bring better development and promotion to the entire industry force.