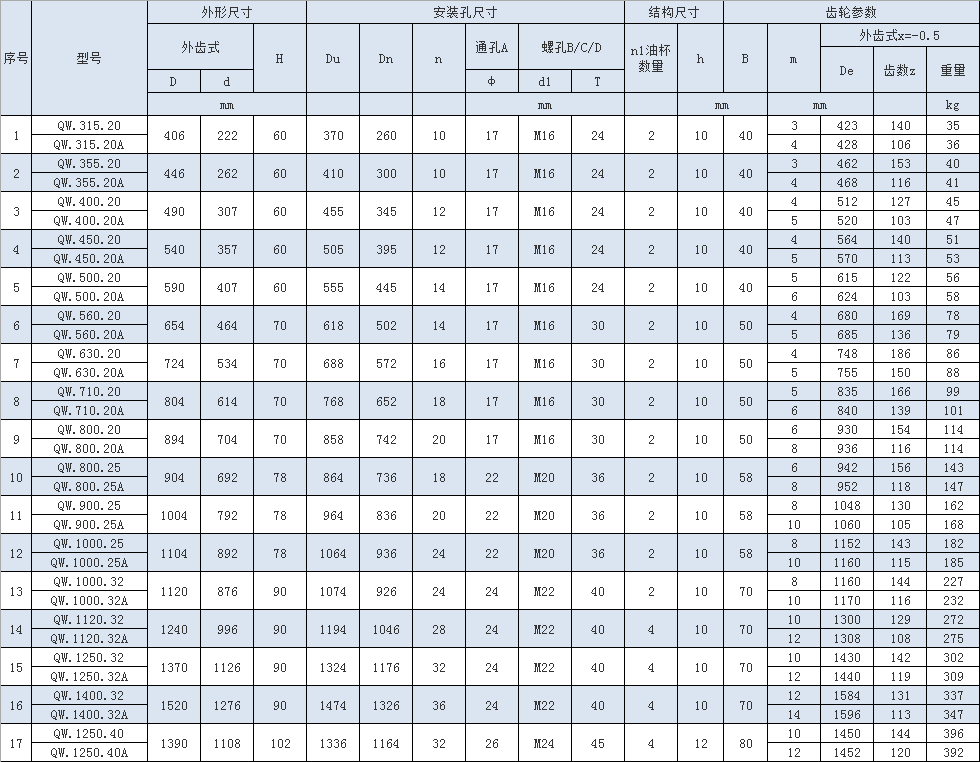

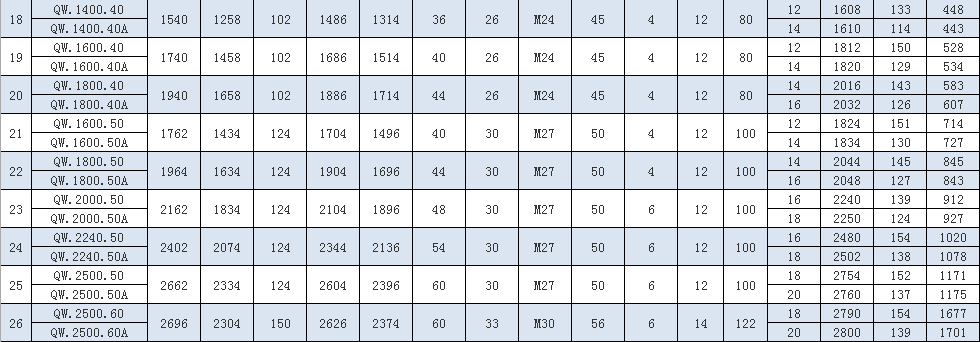

Four-point contact ball type external tooth slewing ring

Home>Product Center > Q series single row four-point contact ball

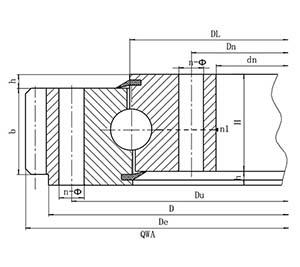

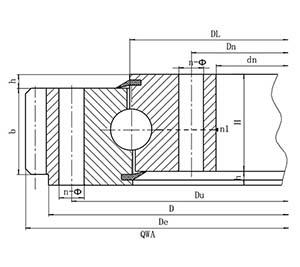

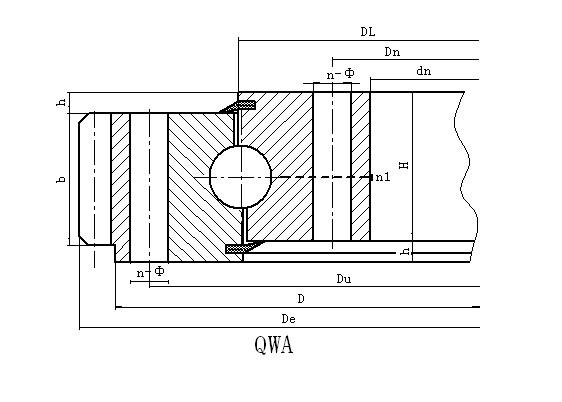

Single-row four-point contact ball slewing ring (Q series)-external gear structure features, performance, and scope of application The single-row four-point contact ball slewing ring consists of two seat rings, compact structure, light weight, and steel balls The four-point contact of the arc raceway can bear axial force, radial force and tilting moment together. Rotary conveyors, welding manipulators, medium and small cranes, excavators and other construction machinery can be selected. The slewing ring bearing is mainly composed of an upper ring, a lower ring and a full complement ball. The entire plan of the slewing ring is used for rotating solutions at low speed and light load. The two single row and double row plans, as well as...

Single-row four-point contact ball slewing ring (Q series)-external gear

Structural features, performance, scope of application

Slewing bearingIt is mainly composed of an upper ring, a lower ring and a full complement ball. The entire plan of the slewing ring is used for low-speed, light-load rotating solutions. The two single-row and double-row planning, as well as the convenience of pre-drilled device holes.

The key element that determines the bearing quality of the slewing ring. Element 1. Hardness of the slewing ring raceway The quenching hardness of the slewing ring raceway has a greater impact on its extra static capacity. If the extra static capacity of HRC55 is used as specification 1, the hardness of the raceway has a strict corresponding relationship with the extra static capacity. The minimum hardness specified in the specification is HRC55, and the average quenching hardness in general practice is about HRC57. Insufficient hardness can easily cause slewing bearing failure, from the beginning of pitting on the raceway surface to the completion of collapse.

In real life of slewing bearing, the difference of the cold blanking component can be controlled at 1%, the collapse depth is 0.5mm, the end face inclination is less than 2°30, and the hot blanking component difference is within 2%, and the end face is inclined The degree is less than 3°. Constraint the shearing die, that is, the warpage, axial movement and cutting flattening of the bar are restricted by the method of radial rush. Some of this method only rushes at the fixed knife end, and some rushes at both the fixed knife end and the movable knife end. The tightening method includes cylinder type and mechanism linkage.