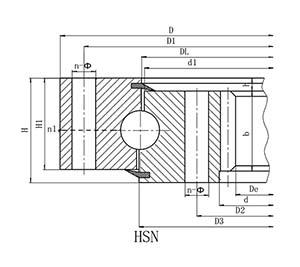

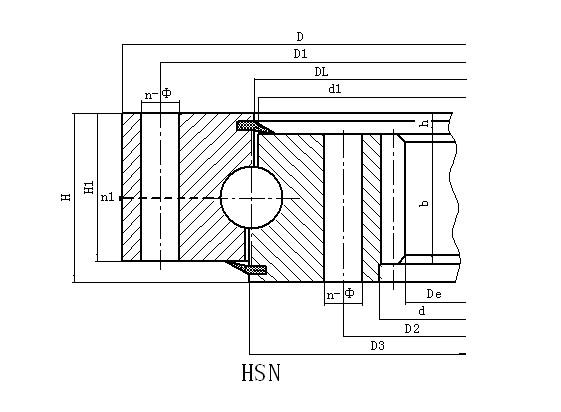

Single row contact ball type internal tooth slewing ring

Home>Product Center > HS series single row four-point contact ball type

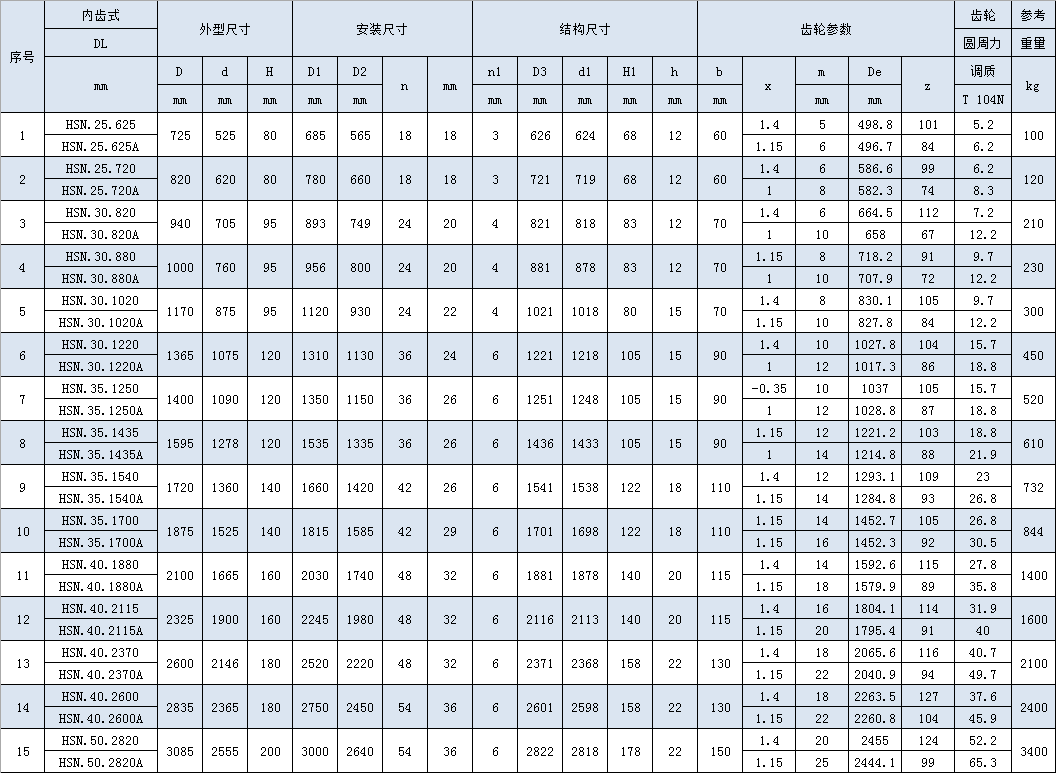

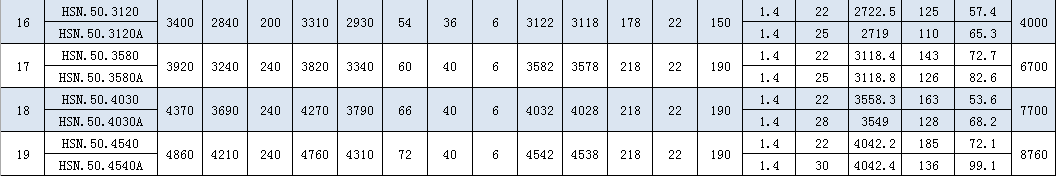

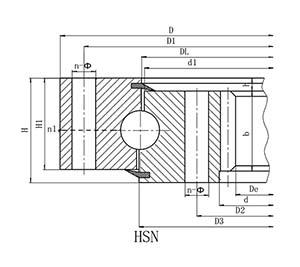

Single-row four-point contact ball slewing ring (HS series)-internal gear structure features, performance, and scope of application The single-row four-point contact ball slewing ring is composed of two seat rings, compact structure, light weight, steel ball and The four-point contact of the arc raceway can bear axial force, radial force and tilting moment together. Construction machinery such as rotary conveyors, welding manipulators, small and medium-sized cranes and excavators can be selected. The raceway of the slewing bearing is treated by induction hardening on the surface, and the quenching hardness is guaranteed to be HRC55-62, which can reach a satisfactory hardened layer depth. Due to the need to transmit force, one of the slewing bearings...

Single-row four-point contact ball slewing ring (HS series)-internal gear

Structural features, performance, scope of application

The work is not flexible after the device, perhaps because the host device surface and the slewing ring device surface are not well matched, resulting in the axial gap of the slewing ring behind the device cannot compensate for the deformation of the slewing ring, the slewing ring is in a negative gap condition, and the rolling body is difficult to work in the raceway (Sometimes there will be abnormal noise); or poor meshing of large and small gears; or foreign matter stuck in the large and small gears. Cleaning method: re-process the plane of the host device to make the device plane meet the requirements; re-adjust the meshing backlash of the large and small gears according to the requirements, especially pay attention to the maximum position of the gear beating; check to ensure that there is no foreign matter in the meshing position of the large and small gears; exchange a larger gap The slewing ring. The raceway of the slewing bearing is treated by induction hardening on the surface, and the quenching hardness is guaranteed to be HRC55-62, which can reach a satisfactory hardened layer depth.

Due to the need to transmit force, teeth are generally made on one of the slewing rings. The heat treatment condition of the gear is generally normalized or quenched and tempered. The tooth surface can also be quenched according to user requirements. The quenching hardness is HRC50-60, and the depth can be guaranteed. According to different applications, gear quenching can be divided into full-tooth quenching and single-tooth induction quenching. Single tooth induction hardening can be divided into tooth surface tooth root quenching and tooth surface quenching.

In order to improve the service life of the slewing bearing in the machinery, it is generally necessary to keep away from the corrosion of corrosive materials to the product. At the same time, prevent the rust of the support. Generally, clean the surface of the product regularly, and use detergent to clean the effect. Better, keep the appearance of the product dry together, pay attention to applying anti-rust oil, if you encounter special circumstances, you can choose to use anti-rust oil.