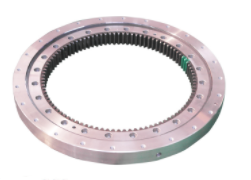

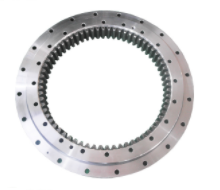

Single row contact type external tooth slewing ring

Home>Product Center > HS series single row four-point contact ball type

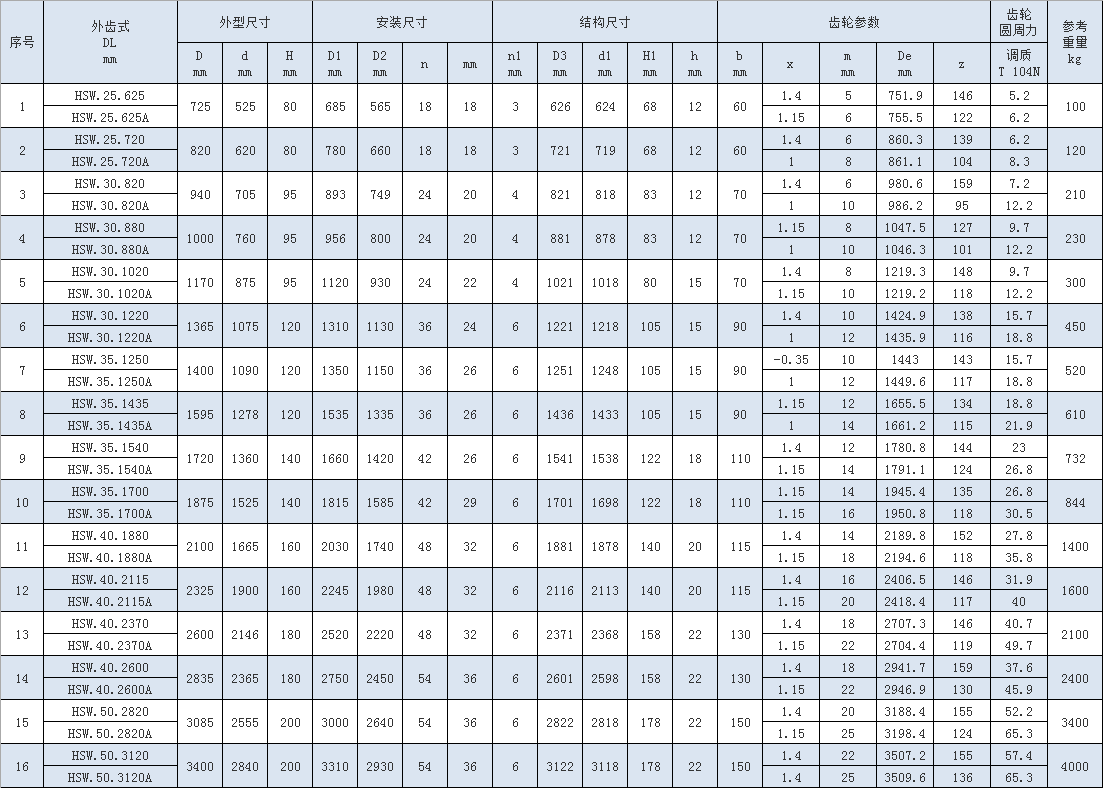

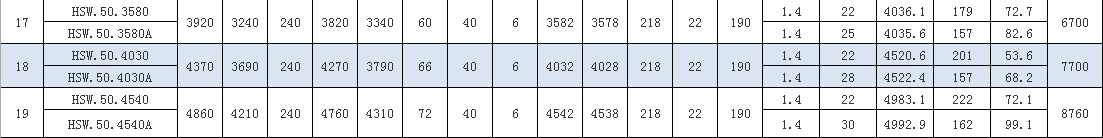

Single-row four-point contact ball slewing bearing (HS series)-external gear structure features, functions, and scope of application The single-row four-point contact ball slewing bearing is composed of two seat rings, with compact structure, light weight, and steel balls. The four-point contact of the arc raceway can simultaneously receive axial force, radial force and tilting moment. Construction machinery such as rotary conveyors, welding manipulators, small and medium-sized cranes and excavators can be selected. Slewing bearing is an important transmission component, which can complete relative slewing motion. It needs to receive various forces during operation. With the wide application of various machinery and equipment in my country, slewing bearing is equipment...

Single-row four-point contact ball slewing ring (HS series)-external gear

Structural features, functions, scope of application

Slewing bearing is an important transmission component, which can complete relative slewing motion. It needs to accept various forces during operation. With the wide application of various mechanical equipment in our country, slewing bearing is an indispensable part of the equipment and is widely used. It has been highly recognized in various types of construction machinery, medical machinery and equipment, and industrial equipment. The single-row four-point contact ball slewing ring is composed of two seat rings, compact structure, light weight, four-point contact between the steel ball and the arc raceway, and can receive axial force, radial force and tilting moment at the same time. Construction machinery such as rotary conveyors, welding manipulators, small and medium-sized cranes and excavators can be selected.

When the slewing bearing is greased, the slewing bearing should be slowly rolled to make the grease filled evenly. The tooth surface should be removed frequently. You can choose and add grease according to your own situation. The first 100 hours of transfer should be timely Check the pre-tightening force of the bolt and check it every 500 hours of rolling in the future to ensure that it has sufficient pre-tightening force. It is forbidden to wash the slewing bearing with water to prevent water from entering the raceway and prevent hard objects from entering the tooth meshing area. Check the seal regularly Integrity, if found to fall off, it should be reset in time.

Note:

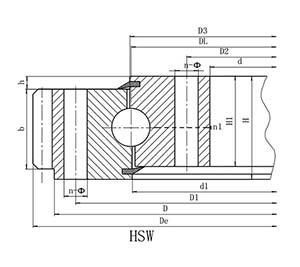

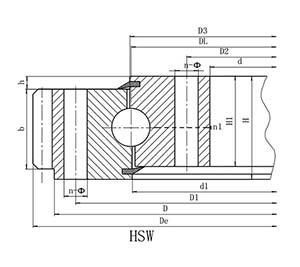

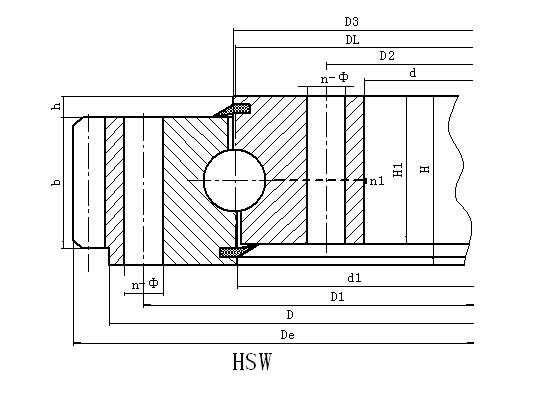

1. The mounting hole n-Φ can be changed to a screw hole; the tooth width b can be changed to Hh.

2. The modification coefficients in the table are all external gear planning.