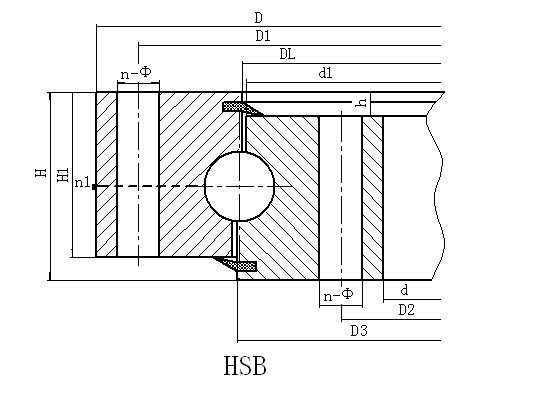

Single row contact ball type toothless slewing ring

Home>Product Center > HS series single row four-point contact ball type

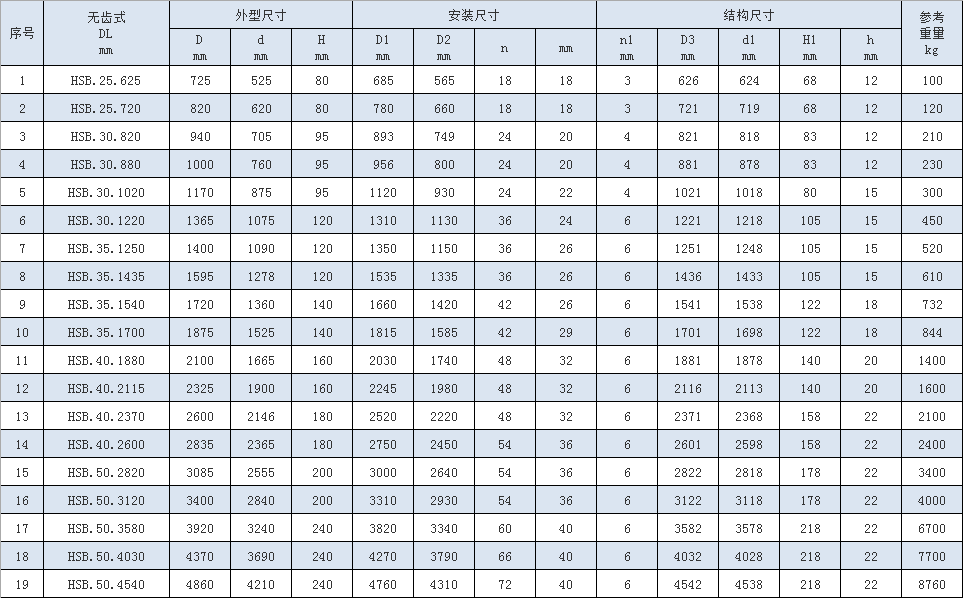

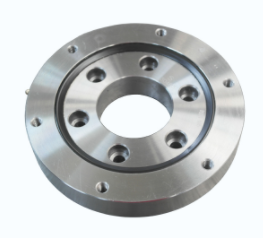

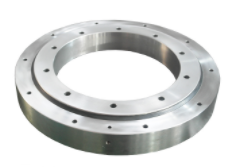

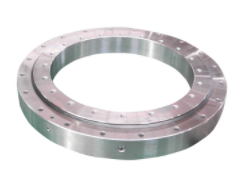

Single-row four-point contact ball slewing ring (HS series)-gearless structure features, performance, and scope of application The single-row four-point contact ball slewing ring is composed of two seat rings, compact structure, light weight, steel ball and The four-point contact of the arc raceway can bear axial force, radial force and tilting moment together. Construction machinery such as rotary conveyors, welding manipulators, small and medium-sized cranes and excavators can be selected. To increase the service life of the slewing bearing in the machinery, it is generally necessary to keep away from the corrosion of corrosive materials on the product. At the same time, the rust prevention measures of the support should be taken. Generally, the appearance of the product should be cleaned regularly....

Single-row four-point contact ball slewing ring (HS series)-gearless

Structural features, performance, scope of application

To improve the service life of the slewing bearing in the machinery, it is generally necessary to keep away from the corrosion of corrosive materials on the product. At the same time, prevent the rust of the support. Generally, the surface of the product is cleaned regularly, and the cleaning effect is better with detergent , Keep the product surface dry together, pay attention to applying anti-rust oil, if you encounter special conditions, you can choose to use anti-rust oil. In fact, the slewing bearing is a very precise product. Don't touch it with your hands when not in use to avoid corrosion to the support.

The slewing bearing is modified with No. 2 extreme pressure lithium-based grease when it leaves the factory. When it is activated, it should be filled with new grease from the beginning according to different working conditions. The raceway of the slewing bearing should be filled with grease regularly. Refuel every 100 hours of operation, and refuel every 50 hours of roller bearings. In special circumstances, such as tropical weather, high humidity, dust, and large temperature differences, the smoothing cycle should be shortened during continuous operation. It is necessary to add new smoothing grease before and after the machine is suspended for a long time. It is necessary to roll each time it is smooth. Fill the channel with smooth grease until it seeps out from the sealing belt