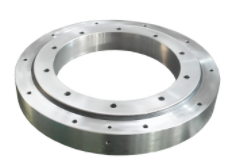

Contact ball type toothless slewing ring

Home>Product Center > 01 series single row four-point contact ball

Single-row four-point contact ball slewing ring (01 series)-gearless structural features, performance, and scope of application The single-row four-point contact ball slewing ring is composed of two seat rings, with compact structure, light weight, and steel balls. The four-point contact of the arc raceway can bear axial force, radial force and tilting moment together. Construction machinery such as rotary conveyors, welding manipulators, small and medium-sized cranes and excavators can be selected. The slewing bearing can work normally at -300C~+700C. If the user needs to adapt to a lower or higher temperature slewing bearing, our company can make special plans. If the slewing ring is in special...

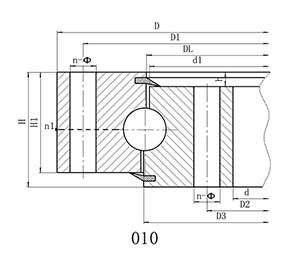

Single-row four-point contact ball slewing ring (01 series)-gearless

Structural features, performance, scope of application

The slewing bearing is an important transmission component necessary for a machine that requires relative rotational movement between two objects, but also needs to receive axial force, radial force, and tilting moment at the same time. With the development of my country’s real economy, my country’s machinery industry has developed rapidly, and it is called: "machine joints" slewing bearings are widely used in ship equipment, construction machinery, light industry machinery, metallurgical machinery, medical machinery, industrial machinery and other industries. . To ensure the safe operation of the slewing bearing, it often involves the production and processing of the slewing bearing, and the entire process of device operation. Construction machinery such as rotary conveyors, welding manipulators, small and medium cranes, and excavators can all be used. The slewing bearing can work normally at -300C~+700C. If the user needs to adapt to a lower or higher temperature slewing bearing, our company can make special plans. If the slewing bearing is used in a particularly harsh environment, such as ocean climate, dust or abrasive particles, sand dust, cement, coal powder, etc. It is necessary to select special sealing rings, protective equipment, and suitable oil passages. Therefore, in order for your support to have a normal effect, we hope to do daily maintenance and maintenance operations.

Note:

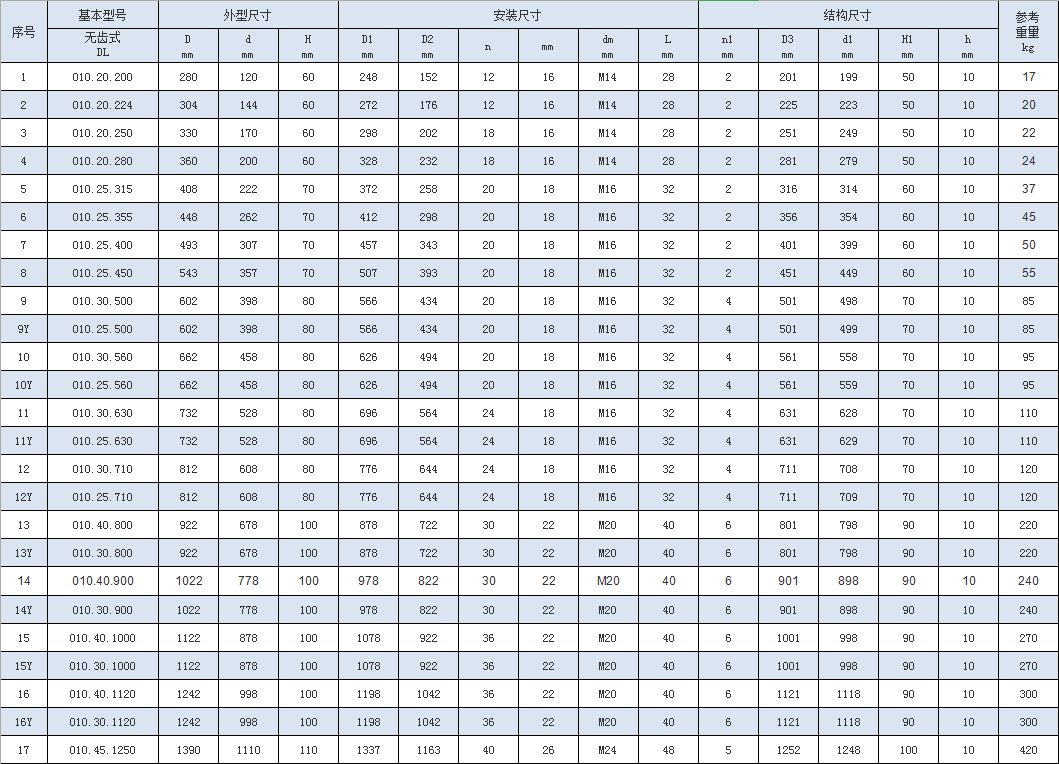

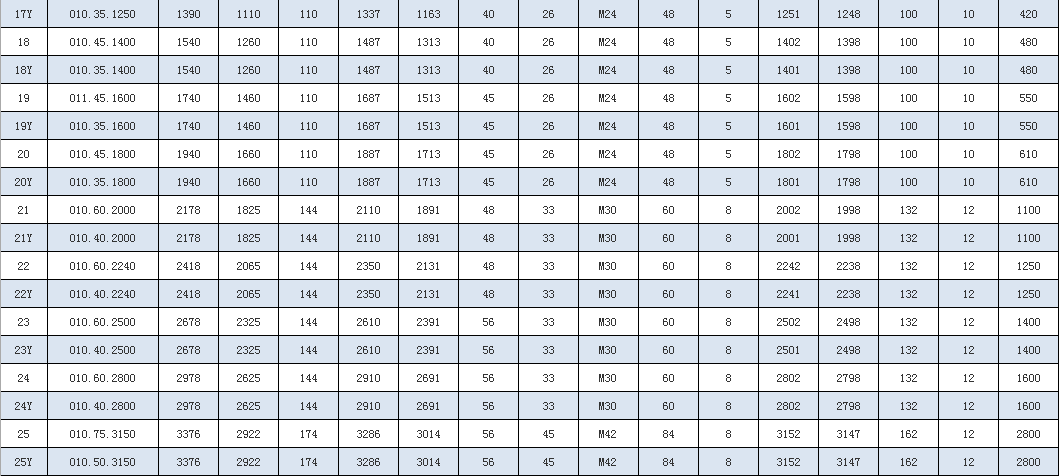

1. n1 is the number of lubricating oil holes, evenly distributed: oil cup M10×1 JB/T7940.1-JB/T7940.2

2. The device holes n-dn1 and n-dn2 can be changed to screw holes; the tooth width b can be changed to Hh.

← No Information