行业知识

Home>Industry knowledge>Content

The slewing bearing is also called a slewing bearing, which can simultaneously accept large axial loads, radial loads and overturning moments and other comprehensive loads. Generally, slewing bearings are equipped with mounting holes, lubricating oil holes and sealed installations, which can meet all kinds of hosts working under different working conditions; in addition, the slewing bearing itself has compact structure, easy to guide rotation, simple installation and simple protection, etc. Features, widely used in engineering, mining, metallurgy, wind power, ships, ports, petroleum, chemical, light industry, medical equipment, food, vehicles, robots, aerospace, radar and military industry and other occupations in large-scale reverse installation.

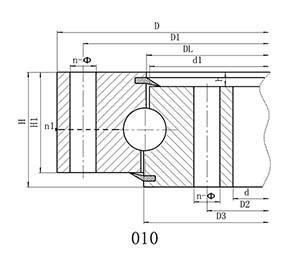

Slewing bearings can be divided into four-point contact ball slewing bearings, interspersed cylindrical (tapered) roller slewing bearings, double-row four-point contact ball slewing bearings, double-row reducing ball slewing bearings, ball-roller combinations and Three-row cylindrical roller combined slewing bearings and other different structural types; the above-mentioned various types of bearings are divided into different structures such as gearless, external gear or internal gear according to whether they have teeth and the distribution of gear teeth.

According to different structural features, the slewing bearing can meet the needs of working hosts under various load conditions. Among them, the four-point contact ball slewing bearing has a higher dynamic load capability, and the interspersed cylindrical roller slewing bearing has a higher static load capability. The three-row cylindrical roller combined slewing bearing leads to the height direction of the bearing because of the increased load capacity. , Various loads are received by different raceways and roller groups. Therefore, under the same stress conditions, the diameter of the raceways is greatly reduced. It has the characteristics of making the host more compact. It is a slewing bearing with high load capacity.