Light series slewing ring (thin type)-internal tooth slewing ring is an indispensable part of construction machinery. The slewing ring of the machine can better drive the operation of the website and reduce the wear between the machinery. In order to better improve the life of the slewing ring, it is necessary to add grease to the slewing ring in time to reduce wear and increase the life. So, how should the slewing ring be greased? Slewing bearing introduction: when adding grease to the slewing bearing, fill in the raceway. There are oil holes or grease nozzles on the outer wall or surface of the slewing bearing. Use a grease gun to inject grease. Add 2 when adding grease to the slewing bearing in winter...

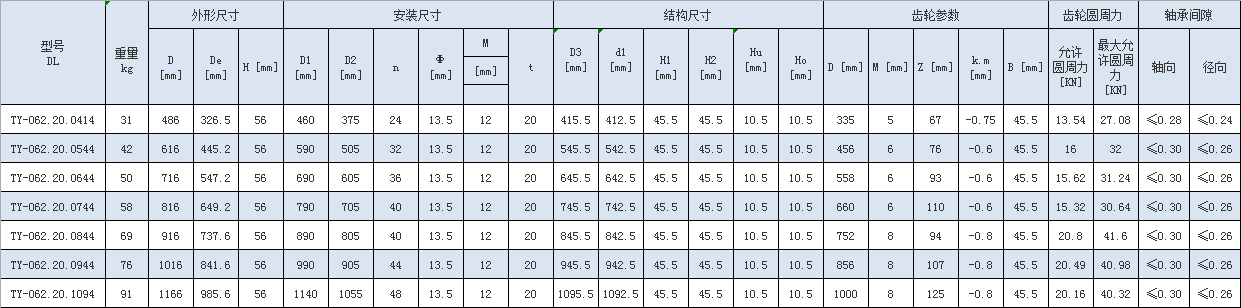

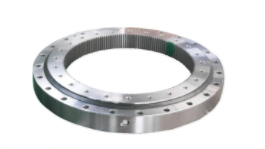

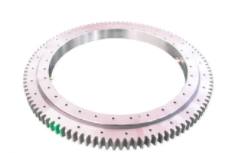

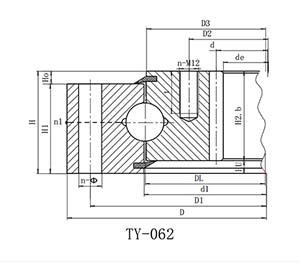

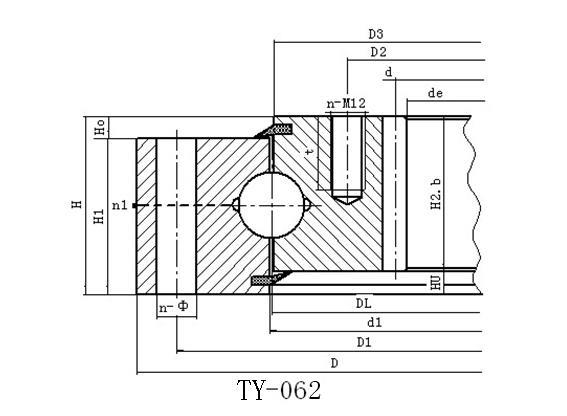

Light series slewing ring (thin type)-internal gear type

Thin slewing bearing is an indispensable part in construction machinery. The slewing bearing of the machine can better drive the operation of the website and reduce the wear between the machinery. In order to better improve the life of the slewing bearing, it is necessary to add grease to the slewing bearing in time to reduce wear and increase the life. So, how should the slewing ring be greased?

Slewing bearing introduction: when adding grease to the slewing bearing, fill in the raceway. There are oil holes or grease nozzles on the outer wall or surface of the slewing bearing. Use a grease gun to inject grease. Add 2# lithium grease to the slewing bearing in winter and 3# lithium grease in summer. When adding grease, a small amount of lubricating oil is generally added during production, and it must be filled with lubricating oil during construction site operation.

At the same time, when the slewing bearing is filled with grease, the gear is filled with grease, and generally the entire ring of teeth needs to be filled. The slewing bearing of the main machine needs to be filled with grease every 100 hours of work, which can effectively reduce the wear between the slewing bearings and improve the service life of the slewing bearing.