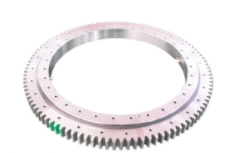

Light series slewing bearings (thin type)-external gear slewing bearings are widely used in the actual industry and are called "joints of machines". The slewing bearing is an important transmission component necessary for a machine that performs relative slewing motion between two objects and needs to bear axial force, radial force, and tilting moment at the same time. With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, construction machinery, light industry machinery, metallurgical machinery, medical machinery, industrial machinery and other industries. The manufacturing process of the slewing ring and the abnormal noise during the working process of the slewing ring are not the problem of lack of lubricating oil. It may be the slewing ring....

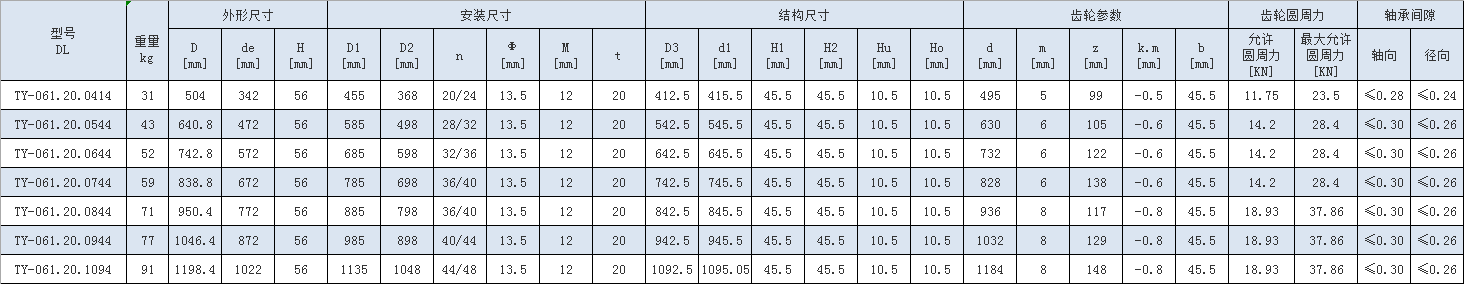

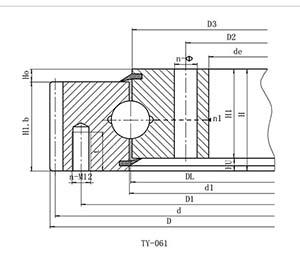

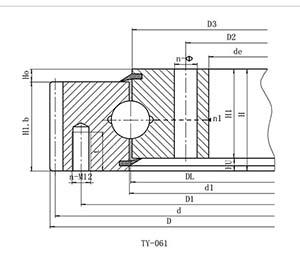

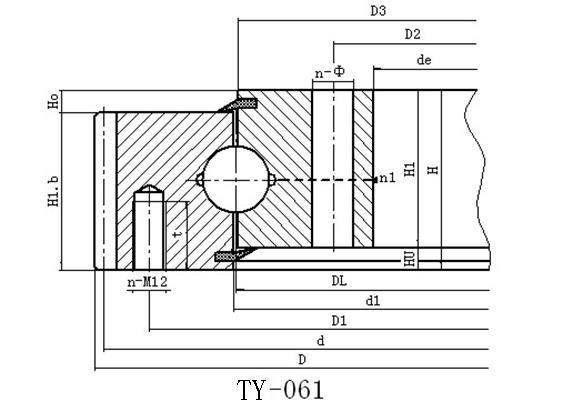

Light series slewing ring (thin type)-external gear type

Slewing bearings are widely used in actual industry and are called "joints of machines". The slewing bearing is an important transmission component necessary for a machine that performs relative slewing motion between two objects and needs to bear axial force, radial force, and tilting moment at the same time. With the rapid development of the machinery industry, slewing bearings have been widely used in marine equipment, construction machinery, light industry machinery, metallurgical machinery, medical machinery, industrial machinery and other industries.

Slewing bearingThe abnormal noise during the manufacturing process and the use of the slewing ring is not a problem of lack of lubricating oil. It may be that a part of the slewing ring is defective or damaged. It is necessary to stop the slewing ring for a detailed and comprehensive inspection. It is often used in various construction machinery industries, and it is also selected for use in ports and ships. Because the slewing bearing is manufactured through the processes of material selection-processing-heat treatment-quenching-cooling processing-viewing-packaging during the manufacturing process, and after manufacturing, it must be inspected by professionals before it can be officially used.