Double-row ball type internal tooth slewing ring

Home>Product Center > 02 series double row ball slewing ring

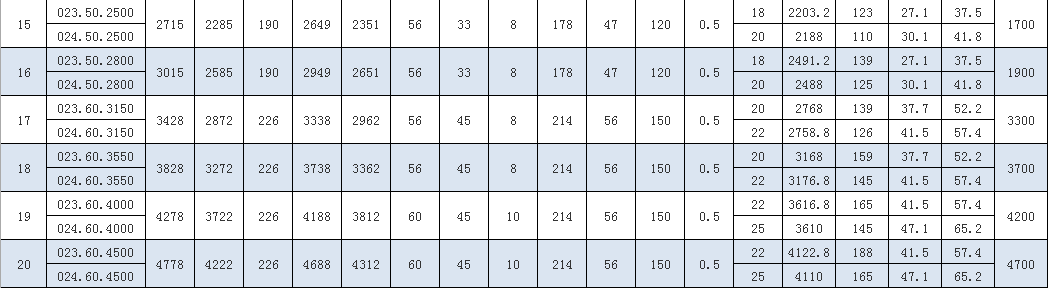

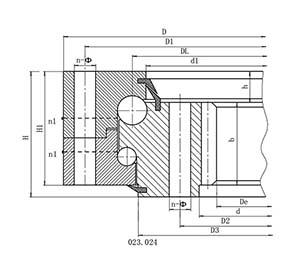

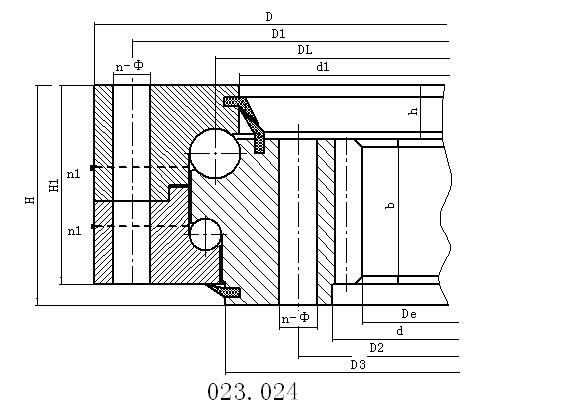

Double-row ball slewing bearing (02 series)-internal gear structure features, performance, and scope of application The double-row ball slewing bearing has three seat rings. The steel balls and barrier blocks can be directly discharged into the upper and lower raceways. According to the force condition, Two rows of steel balls with different diameters are organized. This kind of open device is very convenient. The load-bearing angle of the upper and lower arc raceways is 90°, which can accept a large axial force and tilting moment. When the radial force is greater than 0.1 times the axial force, the raceway must be specially designed. The axial and radial dimensions of the double-row ball slewing ring are relatively large, and the structure is tight. Especially suitable for tower cranes that require medium diameter or above...

Double-row ball type slewing ring (02 series)-internal gear type

Structural features, performance, scope of application

Slewing bearing is a new type of mechanical parts that has gradually emerged in the world in the past four decades. It consists of inner and outer rings, rolling bodies, etc. At present, the slewing bearing of excavators produced in my country is a large-scale bearing that can accept comprehensive loads. , Can accept larger axial and radial load and overturning moment at the same time.

When the radial force is greater than 0.1 times the axial force, the raceway must be specially designed. The axial and radial dimensions of the double-row ball slewing ring are relatively large, and the structure is tight. It is especially suitable for loading and unloading machinery such as tower cranes and car cranes that require medium or larger diameters.

When the slewing ring is collapsed, connect the outer ring of the slewing ring to the upper car, the inner ring to the lower car, and the seal ring on the slewing ring is clean and put away. The equipment is separated by a crane and the slewing ring Remove the screws and bolts on the support. After taking out all the steel balls and barrier sleeves, inspect the steel balls and barrier sleeves. If there are cracks or damages on the barrier sleeves, replace them in time. Inspecting the steel balls is to clean the steel balls and place them in the sun. By watching, you can clearly see whether there are pits or pits on the steel ball.