Double-row ball type external tooth slewing ring

Home>Product Center > 02 series double row ball slewing ring

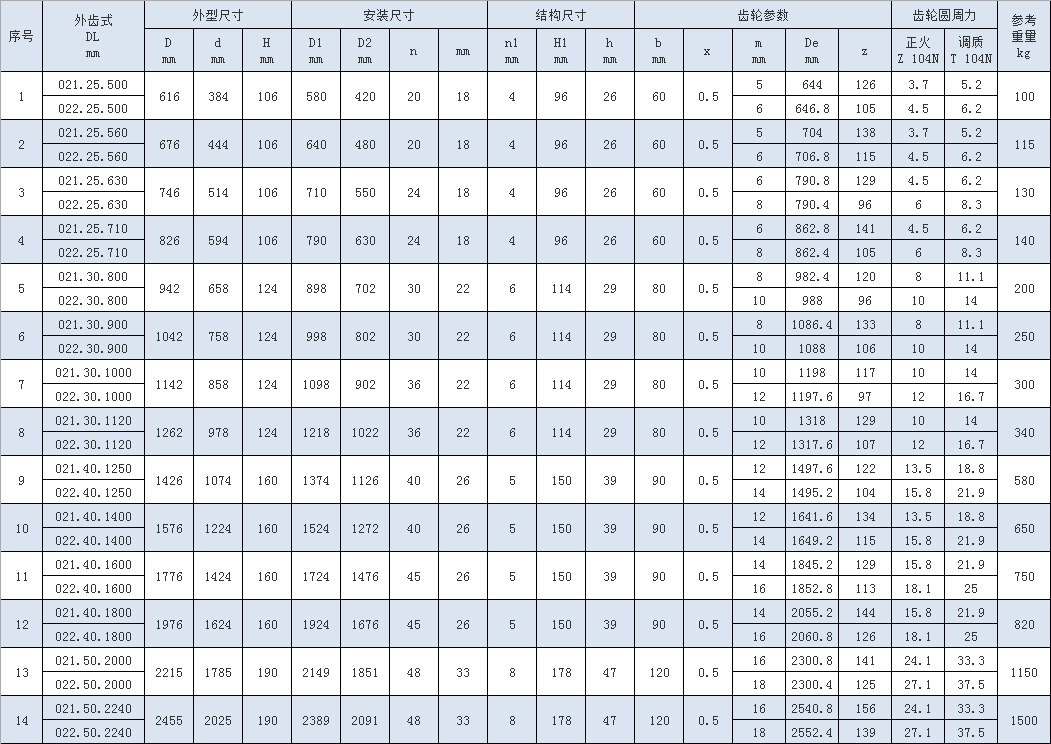

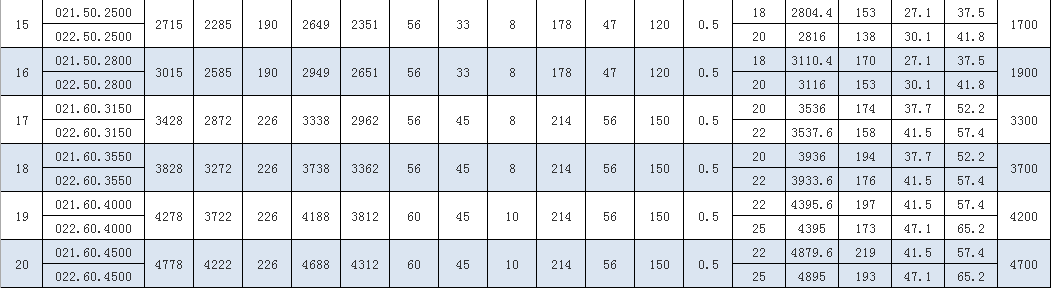

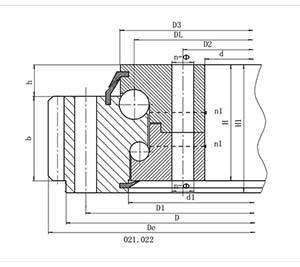

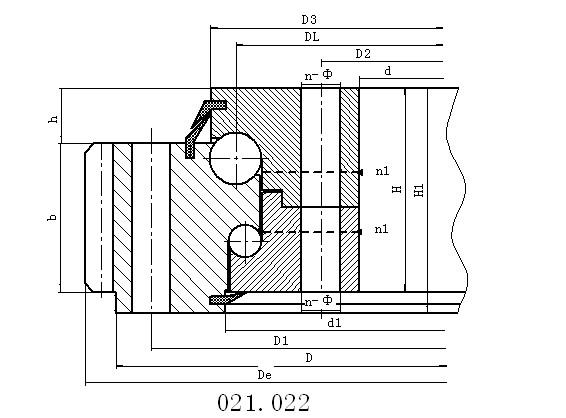

Double-row ball slewing bearing (02 series)-external gear structure features, performance, and scope of application The double-row ball slewing bearing has three seat rings. The steel balls and spacer blocks can be directly discharged into the upper and lower raceways. According to the force condition, Two rows of steel balls with different diameters are organized. This kind of open device is very convenient. The load-bearing angle of the upper and lower arc raceways is 90°, which can accept a large axial force and tilting moment. When the radial force is greater than 0.1 times the axial force, the raceway must be specially planned. The axial and radial dimensions of the double-row ball slewing ring are relatively large, and the structure is tight. Especially suitable for tower cranes that require medium diameter or above...

Double-row ball slewing bearing (02 series)-external gear

Structural features, performance, scope of application

The contact angle α of the raceway of the double-row ball slewing bearing is the angle between the contact point of the steel ball on the raceway and the line connecting the center of the steel ball and the radial section (horizontal plane) of the slewing bearing. Controlling the original contact angle and assembly gap is no longer a simple accuracy problem, but a major issue to ensure the load-bearing capacity and service life. When the radial force is greater than 0.1 times the axial force, the raceway must be specially designed. The axial and radial dimensions of the double-row ball slewing ring are relatively large, and the structure is tight. Small slewing bearings are especially suitable for loading and unloading machinery such as tower cranes and truck cranes that require medium or larger diameters.

The slewing ring is a large bearing that can accept comprehensive loads, and can accept larger axial and radial loads and overturning moments together. Generally equipped with device holes, internal gears or external gears, smooth oil holes and sealing devices, which can make the host design compact, easy to guide and easy to maintain. Bearings have four-point touch balls with or without gears, external gears and internal gears. There are four series of bearings, double-row angular touch ball bearings, interspersed cylindrical roller bearings, interspersed tapered roller bearings and three-row cylindrical roller composite bearings.