行业知识

Home>Industry knowledge>Content

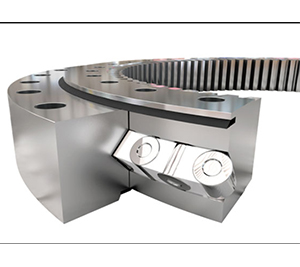

The slewing ring is a large bearing that can bear comprehensive loads, and can bear large radial and axial loads and collapse torque together. The following is a specific introduction to the reasons why the slewing ring cannot use the ductile sealing ring.

1. When the slewing ring is connected with bolts and nuts, the regular anchor bolts are high-strength bolts (level 10.9). The key to the high-strength bolt connection is to rely on the strong frictional resistance between the connected parts to resist external forces, so high-strength bolts do not need to be elastic. pad.

2. The total contact area of the spring washer is not as large as that of the flat washer. There is no flat washer in the place of high moment force. The anchor bolts have a large moment force (such as the 8.8 level and left and right anchor bolts). Torque) will cause plastic deformation of the support point surface near the spring washer. In subsequent use, the enlarged torque of the deformation will be "relaxed". For rotating mechanical equipment, the sensation and collapse torque during operation will be relatively large. If the mouth is opened with a tension spring washer, the sensational crack will be aggravated and the deformation of the slewing ring will be formed.

3. Appropriate flat washers can increase the total area of the supporting points, and can avoid the extrusion and plastic deformation of the anchor bolts formed by the hard and high steel parts at the necessary level, which is beneficial to maintaining the credibility of the torque.

The above is the specific introduction of the reason why the slewing ring can not use the ductile sealing ring. Communication starts from the heart, and the service items are transmitted with emotion, beyond the requirements of customers, and are stronger than satisfying. I hope to cooperate with you.

The company relies on professional technology and advanced service concepts to provide customers with more powerful service and guarantee from ordering, procurement, manufacturing to after-sales. The company’s products are sold throughout the country and have been exported to the United States, Britain, Italy, the Netherlands, Norway, Spain, More than 50 regions, including India, South Korea, Singapore, Thailand, Vietnam, Malaysia, Australia and New Zealand, have been well received by domestic and foreign customers.