行业知识

Home>Industry knowledge>Content

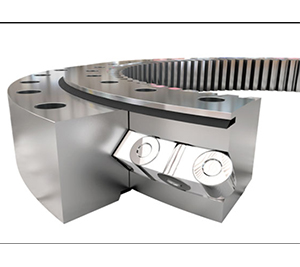

In order to improve the life of the slewing ring, the slewing ring must be maintained before and after work. Today, slewing ring manufacturers talk about maintenance methods after bearing work.

Slewing bearings have very important effects in large construction machinery. In order to prolong the service life of slewing bearings, it is necessary to maintain the slewing bearings. Especially after work, the maintenance of the slewing ring becomes more and more important. Then, how to maintain the slewing ring after work? Most customers have misunderstandings in the maintenance of the slewing ring. They think that the lubricating oil of the slewing ring and the lubrication cycle of the large and small arms are the same, and they are applied every day. In fact, this approach is wrong. If the lubrication period is too short, it will cause too much lubricating oil in the bearing, which will leak out after breaking the dust ring. While there is leakage, impurities will also enter the inside of the bearing, and then endanger the normal operation of the bearing.

Generally, the lubrication interval of slewing bearings is about every 250 hours, and the lubrication period can be adjusted appropriately for different working intensity, and it is appropriate to apply it once a week. The slewing bearing is coated with No. 2 extreme pressure lithium grease when it leaves the factory. When it is activated, it must be filled with new grease from the beginning according to different working conditions. The slewing bearing raceway should be filled with grease on time. General ball bearings Refuel every 100 hours of work, and refuel every 50 hours of roller bearings.

In special circumstances, such as tropical areas, high humidity, dust, and large temperature differences, the lubrication cycle should be shortened during continuous operation. It is also necessary to add new grease before and after the machine is intermittently working for a long time. It is necessary to roll each lubrication. Fill the channel with grease until the leakage from the sealing belt stops. When grease is injected, the slewing ring should be gradually rotated to make the grease filled evenly. The tooth surface should be cleaned of debris frequently. You can choose according to your own situation. Add grease, check the pre-tightening force of the bolts in time after 100 hours of transfer, and check every 500 hours of rotation in the future to ensure that the pre-tightening force is satisfied, and to prevent water from being used to flush the slewing bearing to prevent water entering the raceway Avoid hard objects entering the tooth meshing area, check the integrity of the seal on time, and reset it if it falls.