行业知识

Home>Industry knowledge>Content

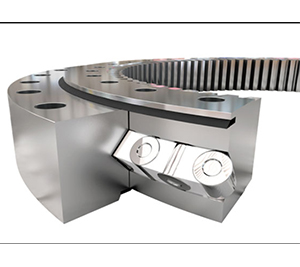

Worm Gear ManufacturersIt is often used to transmit the movement and power between two interweaving shafts. The worm wheel and the worm are equivalent to the gear and the rack in their central plane, and the worm and the screw are similar in shape.

The characteristics of worm gear organization:

1. A large transmission ratio can be obtained, which is more compact than the interwoven shaft helical gear.

2. The worm drive is equivalent to a spiral drive, which is a multi-tooth meshing drive, so the transmission is stable and the noise is small.

3. There is a line touch between the meshing tooth surfaces of the two wheels, and its carrying capacity is much higher than that of the interwoven shaft helical gear organization.

4. Self-locking. When the lead angle of the worm is too small to reach the equivalent friction angle between the meshing gear teeth, the tissue is self-locking and can realize reverse self-locking, that is, only the worm can drive the worm wheel, but the worm wheel cannot drive the worm. For example, the self-locking worm organization used in hoisting machinery, its reverse self-locking can play a role in safety maintenance.

5. The axial force of the worm is relatively large.

6. Low transmission efficiency and severe wear. When the worm gear is engaged in transmission, the relative sliding speed between the meshing gear teeth is large, so the friction loss is large and the efficiency is low. On the other hand, the relative sliding speed means that tooth surface wear is severe and heat generation is severe. In order to dissipate heat and reduce wear, more expensive materials with better friction reduction and wear resistance and good smooth devices are often used, so the cost is higher. .

What materials are generally used to manufacture worms and worm wheels? Why?

Under normal circumstances, the worm is an automatic wheel, and the material is alloy steel with high density, which is not easy to wear; the worm wheel is a driven wheel, and the material is bronze.

The worm wheel uses bronze as the original material because:

1. Bronze has a smooth effect, which helps reduce friction.

2. The bronze texture is relatively soft. Generally, the materials of the worm are harder than the worm wheel. The worm wheel is a passive wheel. The worm is an automatic wheel and is usually connected to the motor. , To protect the motor from being burnt out.