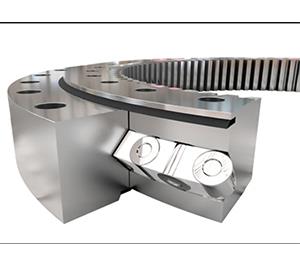

Small slewing bearings will be an indispensable product in mechanical engineering, can accept the radial force, axial force and bearing capacity of the machine, and can better and guarantee the operation of the machine.

Removal of impurities on the surface of small slewing bearings

There will be a seal on the outside of the small slewing bearing. On the one hand, it can prevent the filled grease from leaking out, and on the other hand, it is to prevent external dust, impurities and moisture from entering the inside of the bearing and affecting its normal operation. In order to better prevent the damage of the small slewing bearing, the appearance of the small slewing bearing should be often removed during installation and operation, which can extend its service life and reduce the damage of the small slewing bearing.

In use, we must often remove the external impurities of the small slewing bearing, check whether the sealing strip of the small slewing bearing is aging, cracked, damaged or detached. If one of these conditions occurs, replace the sealing strip in time to prevent debris from entering the raceway Corresponding grease should be applied after replacement to prevent the rolling elements and raceways from jamming or rusting.

Small-sized slewing bearings are inseparable from us. They are used in small-sized slewing bearings no matter in machinery, medical treatment or military. It is also very important to maintain and select small-sized slewing bearings. So, how to choose small slewing bearings? Let me introduce it below

Maintenance method of small slewing bearing

Small slewing bearings can accept increased axial load, rotation, and transmission. Large bearings are often used in machinery, food machinery, and large playgrounds.

1. When installing a small slewing bearing, check the surface of the device to see if there are cracks, burrs and other problems on the surface. At the same time, it must not be misaligned when installing.

2. Check whether there is any looseness after each small slewing bearing operation. If the screw is loose, tighten the bolts. At the same time, clean the small slewing bearing frequently to keep the product appearance clean. Apply lubricant to the slewing bearing.