Common problem one, reducer oil leakage

In order to improve efficiency, worm gear reducers generally use non-ferrous metals as worm wheels, and worms use harder steel. Because it is a sliding friction drive, a lot of heat will be generated during operation, which will cause differences in thermal expansion between the parts and seals of the reducer, thereby forming gaps on each mating surface. The smooth oil becomes thinner due to the increase in temperature and is easy to leak . There are four main reasons for this situation. One is the unreasonable combination of raw materials; the second is the poor quality of the surface of the meshing friction surface; the third is the incorrect selection of the increased amount of smooth oil; the fourth is the poor installation quality and operating environment.

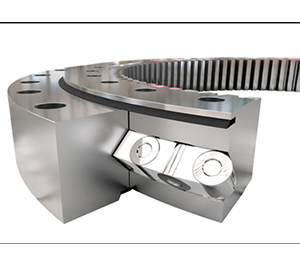

Common problem 2: Worm gear wear

The worm wheel is generally made of tin bronze, and the matched worm material is hardened with 45 steel to HRC45~55, or 40Cr hardened HRC50~55, and then ground to a roughness of Ra0.8μm by a worm grinder. The reducer wears very slowly during normal operation, and some reducers can be used for more than 10 years. If the wear rate is fast, it is necessary to consider whether the selection is correct, whether it is overloaded, and the raw materials of the worm gear, the installation quality or the operating environment.

Common problem three, gear wear

Generally occurs on the reducer installed vertically, mainly related to the increase in lubricating oil and the type of oil. When installed vertically, it is easy to cause insufficient lubrication oil. When the reducer stops working, the transmission gear oil between the motor and the reducer is lost, and the gears cannot be smoothly maintained as they should. When the reducer is started, the gears are not effectively smoothed, causing mechanical wear and even damage.

The above is a summary of the common problems of worm gears and worms made by worm gear manufacturers. I hope it can be helpful to everyone!