As we all know, the slewing bearing itself has the characteristics of compact structure, convenient guidance and rotation, simple equipment and simple maintenance. It is widely used in lifting and transporting machinery, mining machinery, construction machinery, port machinery, wind power generation, medical equipment, radar and missiles. In addition to large rotating equipment such as launchers, the slewing bearing can accept relatively large axial load, radial load and overturning moment and other generalized loads. Structure of large bearings.

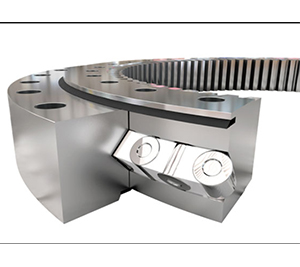

The slewing bearing still occupies a very important position in our daily life and industrial production. It is widely used. In fact, it is mainly because its use has solved many problems in the construction machinery industry. Tooth type and internal tooth type four-point contact ball bearings, double-row angular contact ball bearings, crossed cylindrical roller bearings, crossed tapered roller bearings and three-row cylindrical roller combined bearings and other structural types, in which four-point contact The ball slewing bearing has a higher static load capacity; the crossed cylindrical roller bearing has a higher dynamic load capacity; the crossed tapered roller bearing enables the bearing to have greater support rigidity and higher rotation accuracy through pre-interference energy. Therefore, it has been widely used in the use of construction machinery

Then, the important function of the slewing bearing is to connect the upper and lower parts of the machine, support the weight of the upper part and the load that occurs when the machine is working, and make the upper part of the machine rotate relative to the lower part.

And the use of slewing bearings is very extensive, for example:

1. Trailer: This kind of bearing is used for various purposes, among which the important ones are transportation industry, agricultural trailer, irrigation system and airport luggage rack. In vehicle use, it transmits bearing axial load, radial load and torque. In other uses, they mainly transmit axial loads. LZK specializes in producing rotary bearings for trailers.

2. Wind power generation: Wind turbine bearings generally include yaw bearings, propeller bearings, and drive system bearings (main shaft bearings and gearbox bearings). LZK supplies customers with yaw bearings and pitch bearings. The yaw bearing equipment is in the connecting part of the tower and the cockpit, and the variable propeller bearing equipment is in the connecting part of the root of each blade and the hub. Each wind turbine uses one set of yaw bearings and three sets of pitch bearings.

3. Solar energy: Rotating solar panels is a good way to increase energy. LZK bearings have a very compact design and supply large solar farms in Europe.

4. Medical equipment: The high-precision, low-noise, long-life and high-reliability medical equipment spindle slewing bearing series developed by LZK bearings are widely used in large medical equipment such as gamma knife, CT machine, and nuclear magnetic resonance machine.

5. Robots: industrial robots and other equipment. The turntable bearing equipment is on the joints of the robot, and its design intent is to achieve incredibly tight rotation.

In addition to various engineering machinery, the scale of use of slewing bearings has gradually expanded. Port equipment, metallurgical equipment, drilling channels and other equipment have also begun to use slewing bearings on a large scale to replace the original bearings.