The slewing bearing is a very easy-to-use machine part, and it has very strong functions and assistance. For us, it is very important to develop and research on this product, and it also has a very strong meaning. How to choose and How to use this kind of product? How to strengthen its function, let us understand in detail.

The main thing is to strengthen the hardness, because it is more consolidated, relatively speaking, there will be great progress in wear resistance, so that we can enjoy better use, and we can also have more advantages in the use of parts. Good use experience makes the product more powerful.

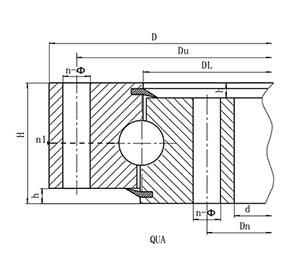

Secondly, the slewing support should also strengthen the improvement and design of the entire structure. The current support has several stable structures. However, if you want better use, it needs to be continuously strengthened and improved in this regard. We bring a stronger role.

It should also be noted that the work rate of support is strengthened. How to improve the share between work and promotion is now a very important concern for such products. If this problem can be solved, we can think of us. Bring better use.

Idling of newly purchased products is not flexible. Please check the production date of the slewing bearing. If it takes a long time, such as more than half a year, and the climate is cold, it may be that the lubricating grease in the raceway is relatively viscous, leading to poor work in cold areas and outstanding in winter. Cleaning method: If it can work and there is no other abnormalities after adding power, it can be used normally; if there is abnormal noise, check whether there are serious wounds during the transportation, and send the information to the service department for processing.

Work is not flexible after installation. It may be that the mounting surface of the main engine and the mounting surface of the slewing ring are not properly matched, resulting in that the axial clearance of the slewing ring after installation cannot compensate for the deformation of the slewing ring. The slewing ring is in a state of negative clearance and the rolling elements are difficult to work in the raceway and sometimes accompanied by abnormal noise Or the large and small gears have poor meshing or there are foreign objects stuck in the large and small gears.